Understanding Plastic Injection Molding Machines

What is a Plastic Injection Molding Machine?

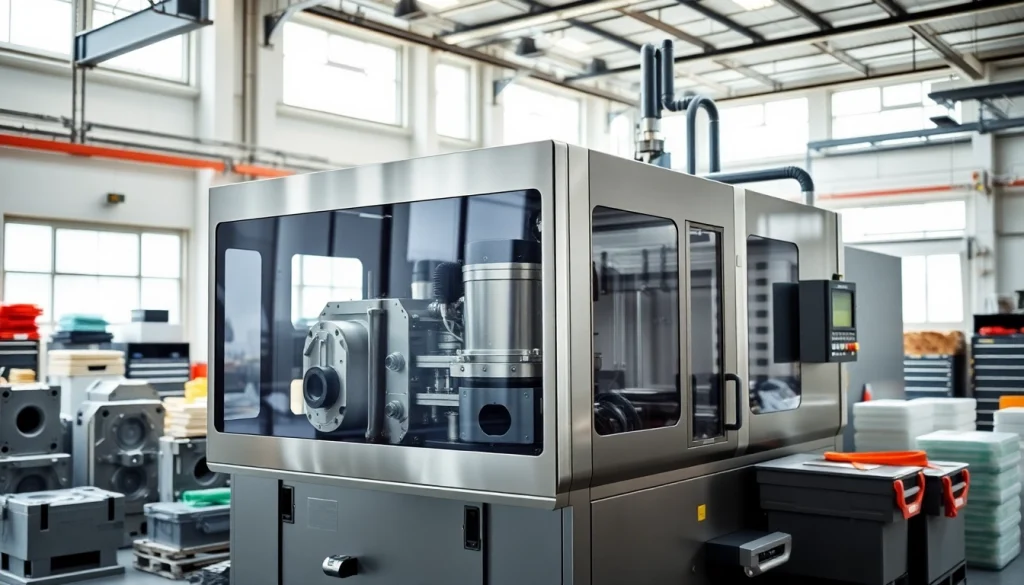

A plastic injection molding machine is a highly efficient manufacturing device that transforms raw plastic materials into finished products through the injection molding process. This process involves melting thermoplastic or thermosetting polymers and injecting them into a mold cavity where they cool and solidify into the desired shape. Common products manufactured by these machines range from everyday household items to intricate components used in automotive and electronics industries.

How Do Plastic Injection Molding Machines Work?

The operation of a plastic injection molding machine can be broken down into several key stages: the clamping phase, injection phase, cooling phase, and ejection phase. First, the machine clamp holds the two halves of the mold securely together before the injection process begins. The next step involves melting the plastic granules in a heated barrel and then injecting the molten material into the mold under high pressure. After the material fills the mold, it cools and solidifies, and then the mold opens to eject the finished part.

Key Components of Plastic Injection Molding Machines

The main components of a plastic injection molding machine include:

- Injection Unit: Responsible for melting the plastic and injecting it into the mold.

- Clamping Unit: Holds the mold halves together during the injection process.

- Mold: The specialized tool where the molten plastic is formed into the desired shape.

- Control System: Provides operators with the ability to monitor and adjust the machine settings.

- Hydraulic or Electric Motor: Powers the machine’s functions either through hydraulic fluid or electric motors, respectively.

Benefits of Using Plastic Injection Molding Machines

Cost-Effectiveness of Injection Molding

One of the most significant advantages of using plastic injection molding machines is their cost-effectiveness. Though the initial investment in machinery and mold creation may be high, the production of large quantities of parts leads to lower per-unit costs. Over time, the economies of scale produced make injection molding one of the most cost-efficient methods for mass production.

Versatility in Design and Production

Plastic injection molding machines offer remarkable versatility in terms of the designs and types of materials that can be used. They can produce complex geometries and intricate details, making them suitable for diverse applications across various industries. Additionally, advancements in material science have expanded the range of polymers that can be molded, allowing for innovations in product design.

Efficiency in Manufacturing Processes

Efficiency is a cornerstone benefit of plastic injection molding. The ability to automate processes means quicker production times. Moreover, precision engineering allows for minimal waste production and high repeatability of parts, resulting in consistency and quality across runs. All these factors contribute to manufacturing more products in less time, thus increasing overall output.

Choosing the Right Plastic Injection Molding Machine

Factors to Consider When Selecting a Machine

Selecting the right plastic injection molding machine involves considering several factors:

- Machine Size and Clamping Force: The size of the machine should match the size of the parts you intend to produce, while the clamping force must be adequate to hold the mold securely.

- Injection Speed and Volume: Depending on production demands, different machines offer various injection speeds and volumes, influencing cycle times and efficiency.

- Energy Consumption: Evaluating the machine’s energy efficiency can significantly affect operating costs over time.

- Material Compatibility: You should ensure that the machine can handle the types of plastics you plan to use.

Top Brands and Models on the Market

When considering the market for plastic injection molding machines, several brands stand out due to their reliability, performance, and customer support. Brands like Arburg, Engel, and Husky are known for their advanced technology and innovative solutions. Each brand offers a range of models tailored to different production needs, allowing manufacturers to choose based on their specific requirements.

Comparison of Different Technologies

There are various technologies employed in plastic injection molding, each with its unique advantages. Traditional hydraulic machines are widely used due to their strength and reliability, while electric machines are becoming increasingly popular for their precision and lower energy consumption. Hybrid machines combine the best of both worlds. Depending on your production demands, it’s essential to analyze these technologies to identify the best fit for your operations.

Common Challenges and Solutions

Addressing Production Inefficiencies

Production inefficiencies can lead to significant losses in profitability. Common issues include machine breakdowns, improper material handling, and inconsistent cycle times. To address these problems, manufacturers should implement regular maintenance protocols, utilize data analytics to track performance metrics, and train employees thoroughly to ensure processes are followed correctly.

Maintaining Machine Performance

To maintain optimal machine performance, it is crucial to monitor various parameters regularly. This includes tracking the temperature and pressure settings within the injection unit, ensuring the hydraulic fluids are changed on time, and keeping the mold clean and free of debris. Peace of mind can also be achieved through predictive maintenance strategies that utilize IoT technology, signaling potential issues before they lead to machine downtime.

Dealing with Material Compatibility Issues

Material compatibility is one of the key challenges in injection molding, particularly when using different plastic types or additives. To mitigate these issues, manufacturers should conduct thorough testing and analysis of all materials being used, ensuring they are suitable for the intended processing conditions. Additionally, close collaboration with material suppliers can offer insights into the best practices for compatibility with specific machines and molds.

Future Trends in Plastic Injection Molding

Advancements in Automation and Technology

The future of plastic injection molding is heavily influenced by advancements in automation. Robotic arms are increasingly used for tasks like part removal and packaging, streamlining the entire manufacturing process. Moreover, the integration of artificial intelligence and machine learning allows for more predictive and efficient operations, significantly enhancing production capabilities.

Sustainability Practices in Injection Molding

As environmental concerns continue to rise, there is a growing demand for sustainable practices in injection molding. Manufacturers are exploring biodegradable materials and recyclable plastics to minimize their environmental footprint. Additionally, implementing energy-efficient technologies and reducing waste through lean manufacturing practices are becoming increasingly important to meet sustainability goals.

Innovation in Material Science

Material science is evolving rapidly, leading to the development of new polymers that offer enhanced performance characteristics. These innovations are resulting in lighter, stronger, and more durable products that can withstand harsher environments. As research continues, we can expect to see even more advanced materials that can open new avenues for product applications in both traditional and emerging industries.