Understanding Diecasting in Malaysia

Diecasting is an essential manufacturing process that has revolutionized various industries by providing high-quality metal components with precise specifications. In Malaysia, this manufacturing technique has gained traction, particularly in automotive, electronics, and aerospace sectors. As a pivotal player in diecasting malaysia, companies are leveraging advanced technologies and skilled labor to meet both local and international demands. This article explores the various facets of diecasting in Malaysia, including its benefits, challenges, innovations, and future prospects.

What is Diecasting? An Overview

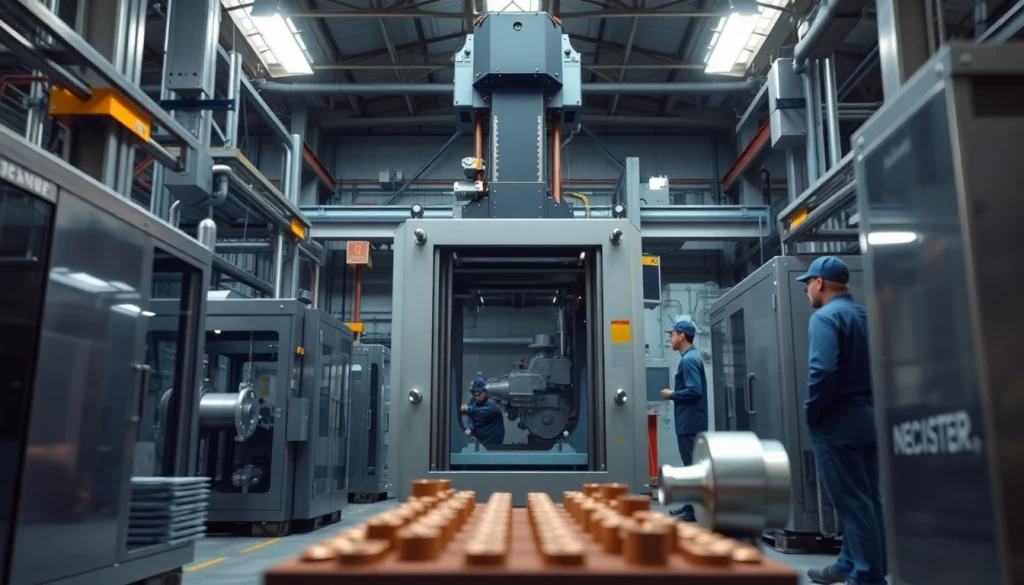

Diecasting is a metal casting process characterized by forcing molten metal under high pressure into a mold cavity. This technique is valued for its ability to produce complex shapes with high dimensional accuracy and smooth surface finishes. Within the manufacturing landscape of Malaysia, diecasting plays a crucial role in producing components for diverse applications, particularly in the automotive and electronics sectors.

The Evolution of Diecasting Methods

Diecasting methods have evolved significantly since their inception. Traditional methods relied on sand casting, which lacked precision and efficiency. However, advancements in technology have propelled the shift toward high-pressure diecasting (HPDC) and low-pressure diecasting (LPDC). HPDC is particularly prevalent in Malaysia due to its capacity for mass production and the high-quality output it delivers. As competition intensifies, Malaysian diecasting firms are adopting these modern methods to enhance productivity and meet international standards.

Key Materials Used in Diecasting Malaysia

The materials selected for diecasting directly impact the quality and performance of the final products. In Malaysia, aluminum and zinc are the most commonly utilized materials due to their favorable properties, such as lightweight, corrosion resistance, and high thermal conductivity. Aluminum diecasting, in particular, has seen a surge in demand due to its versatility and application across various industries, including automotive manufacturing, where reducing weight has become a priority for improving fuel efficiency.

Benefits of Diecasting for Manufacturers

Cost Efficiency and Production Speed

One of the primary advantages of diecasting is its cost efficiency, especially for high-volume production runs. The use of automated processes allows Malaysian manufacturers to reduce labor costs and operational expenses. Additionally, the speed of diecasting outpaces traditional manufacturing methods, enabling quicker turnaround times for clients. This efficiency not only benefits manufacturers but also shortens the time to market for new products.

Enhanced Quality and Precision in Manufacturing

Diecasting is synonymous with high-quality production. The precision of the process ensures that each component meets stringent specifications, minimizing the need for rework or additional manufacturing processes. As companies in Malaysia strive to maintain competitive advantages, the quality benefits of diecasting are pivotal, particularly in industries where performance is critical, such as aerospace and medical devices.

Environmental Considerations in Diecasting

In an era where sustainability is becoming a focal point for manufacturers, diecasting offers several environmental advantages. The process generates less waste compared to other metal forming techniques, and the ability to recycle materials, particularly aluminum, aligns well with eco-friendly practices. Companies in Malaysia are increasingly focusing on sustainable practices, integrating technologies that further reduce their carbon footprint and contribute to a healthier environment.

Challenges Facing Diecasting Companies

Common Misconceptions in Diecasting Practices

Despite the numerous benefits, misconceptions about diecasting persist. Many potential clients mistakenly believe that diecasting is only suitable for high-volume production runs, which can deter smaller businesses from exploring this avenue. However, diecasting can be economically viable for low-to-medium volume productions, particularly with advancements in technology that have reduced setup times and costs.

Regulatory Compliance and Industry Standards

Diecasting companies in Malaysia must navigate a complex landscape of regulatory compliance and industry standards. Adhering to international quality standards such as ISO and ASTM is essential not only for ensuring product quality but also for expanding market accessibility. Companies often invest considerable resources into compliance initiatives to avoid costly penalties and reputational damage.

Addressing Skill Gaps in the Workforce

The diecasting industry faces a significant challenge in terms of skill gaps within the workforce. As technology evolves, the need for a skilled labor force proficient in operating advanced diecasting machines and understanding intricate processes becomes paramount. Education and training programs are critical in developing the necessary skills, ensuring that Malaysia remains competitive in the global diecasting market.

Innovative Techniques in Diecasting

Advancements in Diecasting Technology

Technological advancements are transforming the diecasting landscape in Malaysia. Innovations such as simulation technology enable manufacturers to predict and mitigate potential issues before production begins, significantly reducing waste and enhancing quality. Additionally, the integration of Industry 4.0 concepts, including IoT and AI, aids in optimizing production processes and improving overall operational efficiency.

The Role of Automation in Diecasting Malaysia

Automation is making significant strides in the diecasting industry. Automated systems streamline production workflows, reducing human error and increasing output rates. Malaysian manufacturers are investing in robotic systems for tasks such as material handling and quality inspection, which not only enhance efficiency but also free up skilled labor for more complex tasks. This shift toward automation is essential for maintaining competitiveness in an increasingly globalized market.

Case Studies of Successful Innovations

Several Malaysian diecasting companies have successfully implemented innovative techniques to enhance their operations. For instance, a leading automotive parts manufacturer integrated advanced simulation software which led to a 20% reduction in production time while improving yield rates. Such case studies illustrate how innovation is pivotal for driving growth and maintaining a competitive edge in the dynamic manufacturing environment.

Looking Ahead: The Future of Diecasting Malaysia

Market Trends and Predictions for 2025

The diecasting market in Malaysia is poised for growth, driven by various factors including increased demand for lightweight automotive parts and advancements in technology. Predictions for 2025 indicate a marked increase in the use of diecasting in emerging industries such as renewable energy and electric vehicles. This shift presents vast opportunities for manufacturers willing to adapt to changing market demands.

Investment Opportunities in Diecasting Technologies

With the growing emphasis on sustainability and advanced manufacturing technologies, investment opportunities in diecasting are abundant. Malaysian companies are encouraged to explore partnerships with technology providers to integrate smart manufacturing practices. This approach not only enhances operational efficiency but also positions manufacturers to capitalize on the increasing demand for innovative diecast products.

Preparing for Changes in Consumer Demand

As consumer preferences evolve, Malaysian diecasting companies must remain agile and responsive. The shift towards customization and quick prototyping means that manufacturers should invest in flexible production systems. By harnessing new technologies and understanding market trends, companies can better align their offerings with consumer demands, ensuring long-term sustainability and profitability.