Understanding Injection Molding Machines

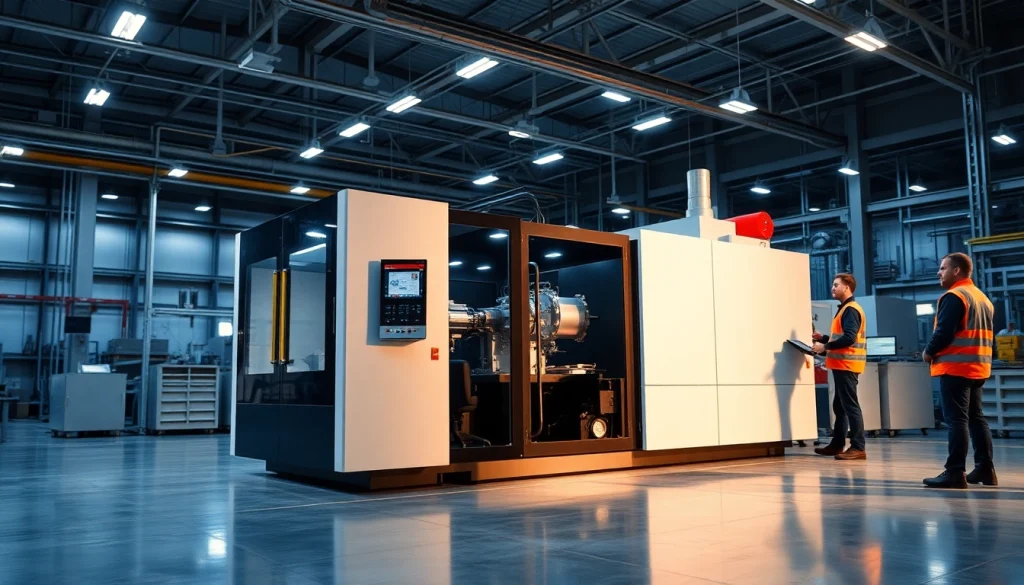

Injection molding machines are pivotal in modern manufacturing, providing an efficient method for producing complex plastic parts and components with precision and speed. These machines utilize a well-defined process where melted plastic is injected into a mold, allowing for the mass production of detailed and consistent products. As industries continue to evolve, the demand for reliable and technologically advanced machines has surged. When exploring options, Injection Molding Machines have emerged as industry leaders, driving innovations that enhance productivity and cost-efficiency.

What is an Injection Molding Machine?

An injection molding machine, often referred to as an injection press, is a critical piece of equipment in the plastic manufacturing sector. It works by melting plastic pellets and injecting the molten material into a pre-designed mold to create specific shapes. The process consists of several key phases: heating, injection, cooling, and ejection. Through this process, manufacturers can produce everything from tiny components to larger industrial parts with high precision.

Types of Injection Molding Machines Available

Injection molding machines can be categorized into three primary types: hydraulic, electric, and hybrid. Each type offers unique advantages tailored to different manufacturing needs:

- Hydraulic Injection Molding Machines: These machines use hydraulic systems for clamping and injection, making them suitable for high-pressure applications and large molds.

- Electric Injection Molding Machines: Known for their energy efficiency and precision, electric machines are ideal for small to medium-sized production runs and applications requiring high repeatability.

- Hybrid Injection Molding Machines: Combining elements from both hydraulic and electric designs, hybrid machines provide flexibility and efficiency, making them versatile for various industrial applications.

Key Components and Their Functions

Understanding the components of an injection molding machine is essential for selecting the right equipment. Key parts include:

- Injection Unit: Responsible for melting the plastic and injecting it into the mold.

- Clamping Unit: Holds the mold in place during the injection and cooling phases to ensure accurate product formation.

- Control System: Manages the entire injection process, adjusting parameters such as temperature, pressure, and timing to optimize production.

Benefits of Electric Injection Molding Machines

Electric injection molding machines are transforming the industry with numerous benefits that make them an attractive option for manufacturers seeking efficiency and quality.

Energy Efficiency and Cost Savings

Electric injection molding machines consume significantly less energy compared to their hydraulic counterparts. By utilizing servo motors for clamping and injection processes, these machines reduce energy waste and lower operational costs. The minimal energy consumption translates to substantial savings, particularly in high-volume production settings.

Enhanced Productivity and Speed

With faster cycle times and reduced downtime, electric machines can improve overall productivity. The precise control of the injection process allows for rapid adjustments, resulting in quicker production rates. This speed is particularly beneficial for industries that demand high-volume output.

Improved Product Quality and Precision

Electric injection molding machines excel in producing high-quality parts with exceptional dimensional accuracy. The consistent injection pressure and temperature control minimize variations in product quality, making it easier to achieve tight tolerances and complex designs without compromising on performance.

Topstar Injection Molding Machines Overview

Topstar’s injection molding machines stand out for their innovative features and efficiency, catering to various industrial needs.

Features of the TEII Series Electric Machines

The TEII Series comprises all-electric injection molding machines ranging from 90T to 460T. Their high-rigidity clamping units stabilize products and protect molds during operation. Key features include a modular design for adaptability, a humanized interactive interface, and optional linear rail support that lightens movement. Such features make the TEII Series ideal for diverse production requirements.

Advantages of the TMII Series Servo-Driven Machines

TMII Series machines, with clamping capacities between 90T and 470T, integrate a servo-driven system for optimal performance. This series enables real-time feedback and communication, allowing for comprehensive control over the injection process. The ability to cooperate with injection molding robots enhances precision in grasping, further improving production efficiency and product quality.

Highlights of the TH Series Direct Press Machines

Available in capacities from 130T to 2800T, the TH Series Direct Press Type Injection Molding Machines are engineered for larger and more complex products. The design features standardized clamping and injection platforms, maximizing mold opening strokes. This configuration is particularly suitable for automatic part-picking applications, enhancing overall manufacturing efficiency.

Choosing the Right Injection Molding Machine for Your Needs

Selecting the appropriate injection molding machine involves careful consideration of various factors related to your production requirements, budget, and operational capabilities.

Factors to Consider Before Purchase

Before investing in an injection molding machine, consider aspects such as:

- Production Volume: High-volume production may necessitate machines with faster cycle times or greater clamping forces.

- Part Complexity: Intricate designs may require advanced features like electric drives and modular designs for precision.

- Budget Considerations: Weigh the initial investment against long-term savings in energy and maintenance costs.

Common Challenges in Machine Selection

Common challenges include matching the machine’s capabilities with production demands, understanding energy consumption, and evaluating maintenance needs. Consulting with manufacturers and reviewing case studies can provide insight into making informed decisions.

Real-World Applications and Use Cases

Injection molding finds applications in diverse industries, including automotive, consumer goods, and medical devices. For instance, the automotive sector uses injection molding to produce components like dashboards and internal features quickly and affordably.

Future Trends in Injection Molding Technology

As technology continues to advance, the injection molding industry is poised for exciting developments that promise to reshape production practices.

Emerging Innovations in Injection Molding Machines by 2025

Future innovations will likely focus on integrating advanced materials, automation, and smart technologies to improve efficiency and product quality. The adoption of artificial intelligence for predictive maintenance and process optimization is also anticipated.

Impact of Automation and Smart Technologies

With the rise of Industry 4.0, automation in injection molding will enhance operational efficiency by reducing human error and improving data collection. This will allow manufacturers to maximize uptime and minimize waste, aligning with sustainability goals.

Anticipated Market Changes and Consumer Demands

As consumer preferences evolve towards sustainable and customizable products, injection molding technology will need to adapt. Manufacturers may need to invest in smaller, more flexible machines capable of rapid changes without compromising production scalability.