Understanding Injection Robots

Definition and Functionality

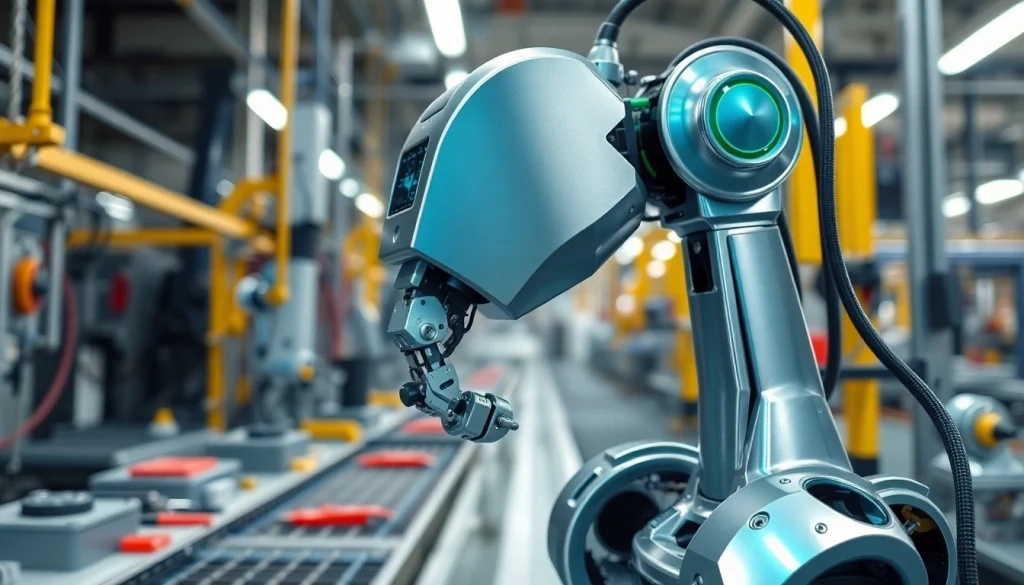

Injection robots are automated machines designed to handle the injection molding process, a manufacturing technique used to create parts by injecting material—most commonly plastic—into a mold. These robots improve precision and efficiency by automating the tasks that would traditionally be performed by human workers. They are particularly valuable in environments where high-speed production and repeatability are critical. For operations large and small, the influence of an Injection Robot extends from the initial material handling to the final quality assurance processes of molded products.

Types of Injection Robots

Injection robots can be classified into several types based on their functionalities and configuration:

- Articulated Robots: These robots feature rotating joints, allowing for a wide range of motion and flexibility in handling complex molds.

- Cartesian Robots: Utilizing linear movement along the X, Y, and Z axes, Cartesian robots are well-suited for tasks requiring precision but less complexity.

- Delta Robots: Known for their speed in picking and placing operations, delta robots are commonly used in high-speed assembly and material handling.

- SCARA Robots: Selective Compliance Assembly Robot Arm (SCARA) robots excel in lateral movements, making them perfect for rapid assembly tasks.

- Collaborative Robots (Cobots): These robots work alongside human operators, providing assistance while ensuring safety and efficiency.

Key Components and Technologies

Understanding the mechanics behind injection robots involves recognizing several critical components and technologies that enhance their capabilities:

- Actuators: These are responsible for movement and precision targeting within the injection drying systems, assisting in maintaining the required pressure and volume.

- Sensors: Sensors provide data for feedback systems, ensuring quality and control over the injection process by monitoring variables such as temperature and pressure.

- Controllers: Advanced software and controllers manage the operation time, synchronization, and the functioning of different components, leading to improved productivity.

- Molds: The design and quality of molds play a crucial role in production; high-quality molds reduce wastage and enhance the production speed.

Advantages of Using Injection Robots

Increased Production Efficiency

The introduction of injection robots leads to significant increases in production efficiency. By automating the injection molding process, manufacturers can achieve higher output levels without compromising quality. Robots can operate continuously, requiring less downtime for maintenance compared to human labor. As a result, the cycle times are reduced, allowing for more parts to be produced in the same timeframe.

Cost Savings and ROI

Investing in injection robots offers impressive cost savings in both operational and labor expenses. While the upfront investment in machinery can be considerable, the long-term return on investment (ROI) often justifies the expenditure. With robotics handling the majority of the labor-intensive tasks, companies experience lower labor costs, reduced defects, and decreased scrap rates which, in turn, improve profit margins. The automation reduces the likelihood of human error, which can lead to costly reworks or discarded products.

Enhanced Quality Control

Quality control is essential in manufacturing, and injection robots significantly enhance this aspect. Equipped with advanced sensors and automated quality monitoring systems, these robots offer consistent and precise production results. Each piece can be checked in real-time for defects, maintaining high-quality standards that would be difficult to achieve with manual processes. For manufacturers, this means reduced return rates from clients and higher customer satisfaction.

Applications Across Industries

Automotive Sector Uses

The automotive industry extensively utilizes injection robots for producing a wide variety of components ranging from interior panels to intricate engine parts. The robots handle multiple tasks, such as removing parts from molds, assembling components, and applying coatings, thereby streamlining the entire process. They also enable the production of lightweight but durable materials, which is essential in modern automotive design.

Consumer Goods Manufacturing

In consumer goods manufacturing, injection robots are crucial for producing everything from plastic containers to intricate parts used in electronics. Their ability to mold complex designs with high efficiency allows companies to meet consumer demands rapidly and cost-effectively. Automated systems not only refine the production process but also facilitate customization, enabling rapid iteration based on market feedback.

Healthcare Equipment Production

In the healthcare sector, precision is non-negotiable, and injection robots ensure that medical equipment is manufactured to the highest standards. Products such as syringes, IV bags, and surgical tools are created with accuracy and sterility in mind. The ability of robots to perform repetitive tasks without fatigue significantly enhances efficiency in tightly regulated environments where quality and compliance are critical.

Challenges and Considerations

Integration with Existing Systems

The integration of injection robots into existing manufacturing systems can present challenges. Companies must assess their current workflows and adapt to integrate these automated systems effectively. This often involves upgrading existing machinery or software to ensure compatibility with new robotic systems. A thorough analysis of the production line and possible reconfiguration is necessary for a successful transition.

Maintenance and Upkeep

Regular maintenance is crucial for ensuring optimal performance of injection robots. Overlooked wear and tear can lead to downtime and costly repairs. Companies should establish a consistent maintenance schedule, including inspections and routine checks of critical components. Additionally, keeping software updated helps in the prevention of potential technical issues associated with robotic operations.

Training Requirements for Workforce

The adoption of robotic technology necessitates specialized training for the workforce. Employees must be equipped with the necessary skills to troubleshoot and collaborate effectively with robotic systems. Companies should prioritize ongoing training programs that cover the operational aspects of both robots and traditional injection molding processes, ensuring workers feel confident and competent in managing the new technology.

Future Trends in Injection Robotics

Advancements in AI and Automation

The future of injection robots is intricately tied to advancements in artificial intelligence (AI) and automation technologies. These robotics systems are increasingly becoming smarter and more autonomous, capable of learning from past operations to optimize future production. The integration of AI allows robots to adapt to variable production demands and automate decision-making processes that can enhance efficiency and reduce waste.

Impacts on Workforce Dynamics

The rise of automation and injection robotics will inevitably influence workforce dynamics. While these machines may displace certain job roles, they can also create opportunities for higher-skilled positions related to programming, maintenance, and operations of these technologies. Companies must therefore strategize for workforce reallocation and involve employees in upskilling initiatives to ease transitions.

Sustainability and Energy Efficiency Improvements

As industries increasingly focus on sustainability, injection robots are also evolving to enhance energy efficiency. Modern machines are designed to consume less energy during operation, leading to lower carbon footprints for manufacturing processes. Implementing these robots not only aligns with corporate social responsibility practices but also meets consumer expectations for ethical manufacturing. The future will see a greater emphasis on eco-friendly materials and production methods facilitated by robotic technology.